Hotel Meeting Room

Hotel Meeting Room

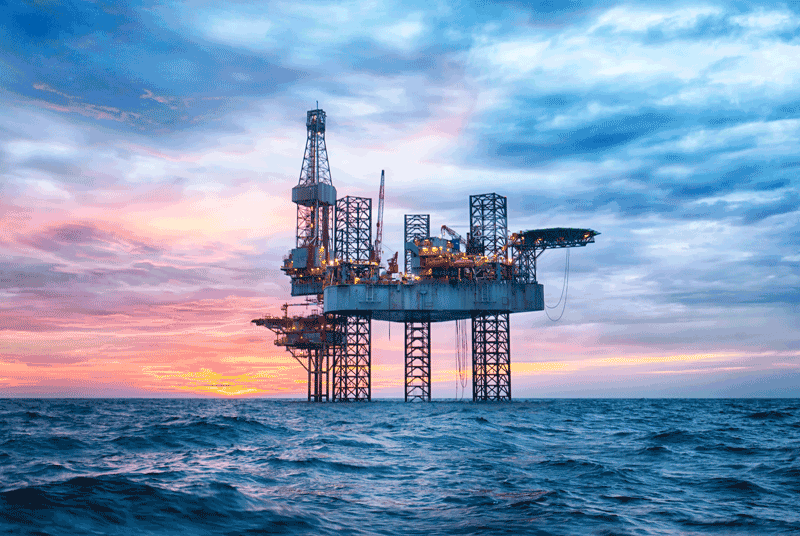

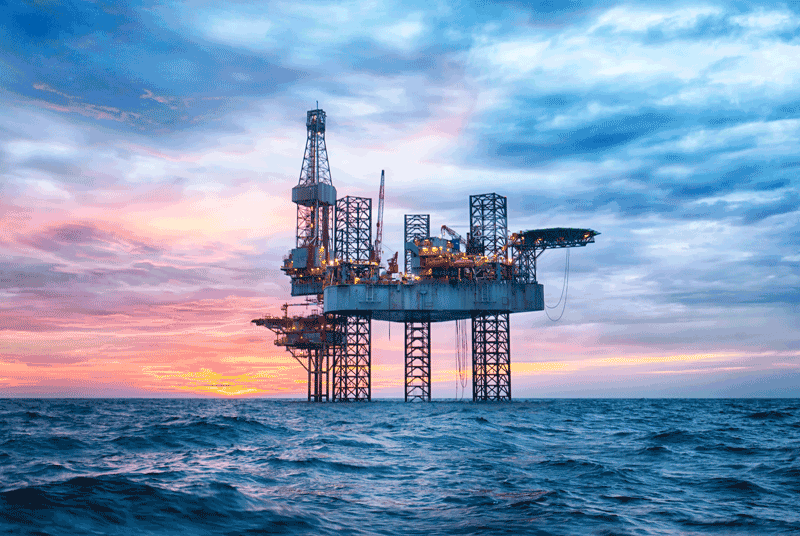

Petroleum, Oil , Gas Training Courses

Petroleum, Oil , Gas Training Courses

Hotel Meeting Room

Hotel Meeting Room Doha

Doha

Classroom

Overview ?

The present state of the art design of piping systems is based on the close interaction and collaboration between system designers and operators. The operator’s experience with running complex piping systems for long periods is an important factor in improving the design. The most delicate design problems are encountered during the expansion of systems, when they are made larger or more complex. For a piping system to operate in a problem-free manner, the design and installation of a piping system requires attention to multiple factors. During the past few decades, pipeline systems and technologies have been progressing at a fast pace in all aspects of the design, operation, and automatic control. The systems have grown in size and intricacy, and today’s trends in the industry are aimed at enlarging the flow rates, pipe diameters and working pressures for a wide variety of fluids to be handled, including very complex and difficult ones. All of these factors impose strong requirements on careful design, precise operation and complex control Pipeline operation engineers and managers have to be sufficiently familiar with the details of fluid flow in piping systems as well as with modern technologies, in order to make informed decisions on various technical aspects of the designed system and its future operation. There is a need for detailed monitoring of everyday operation, as well as computer-based centralized automatic control of operation of large systems. At the same time, environmental concerns and safety issues require highly sophisticated monitoring and control systems.

The course is an assortment of lectures, discussions and workshops with active delegate participation and team work. The focus will be on physical principles and technical reasoning with their justification and clarification. There will be comprehensive workshops with the real-life cases, and calculation procedures with results discussed. A daily dialogue will be held with participants with the goal of reviewing key learnings gained and inspiring delegates to exchange views from professional experiences.

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Pipes and Piping Systems Optimisation

06, Jul 2025 10, Jul 2025

Amman

3250$

Pipes and Piping Systems Optimisation

13, Jul 2025 17, Jul 2025

Marrakesh

3450$

Pipes and Piping Systems Optimisation

20, Jul 2025 24, Jul 2025

Sharm ElShaikh

3250$

Pipes and Piping Systems Optimisation

27, Jul 2025 31, Jul 2025

Doha

4000$

Pipes and Piping Systems Optimisation

03, Aug 2025 07, Aug 2025

Casablanca

3450$

Pipes and Piping Systems Optimisation

10, Aug 2025 14, Aug 2025

Riyadh

3250$

Pipes and Piping Systems Optimisation

11, Aug 2025 15, Aug 2025

Milan

5250$

Pipes and Piping Systems Optimisation

18, Aug 2025 22, Aug 2025

Istanbul

3450$

Pipes and Piping Systems Optimisation

24, Aug 2025 28, Aug 2025

Jeddah

3250$

Pipes and Piping Systems Optimisation

31, Aug 2025 04, Sep 2025

Manama

3250$

Pipes and Piping Systems Optimisation

07, Sep 2025 11, Sep 2025

Beirut

3250$

Pipes and Piping Systems Optimisation

15, Sep 2025 19, Sep 2025

Singapore

5450$

Pipes and Piping Systems Optimisation

21, Sep 2025 25, Sep 2025

Kuwait

3250$

Pipes and Piping Systems Optimisation

28, Sep 2025 02, Oct 2025

DUBAI

3450$

Pipes and Piping Systems Optimisation

06, Oct 2025 10, Oct 2025

Kuala Lumpur

3750$

Pipes and Piping Systems Optimisation

12, Oct 2025 16, Oct 2025

Amman

3250$

Pipes and Piping Systems Optimisation

13, Oct 2025 17, Oct 2025

Milan

5250$

Pipes and Piping Systems Optimisation

19, Oct 2025 23, Oct 2025

Marrakesh

3450$

Pipes and Piping Systems Optimisation

26, Oct 2025 30, Oct 2025

Sharm ElShaikh

3250$

Pipes and Piping Systems Optimisation

02, Nov 2025 06, Nov 2025

Doha

4000$

Pipes and Piping Systems Optimisation

09, Nov 2025 13, Nov 2025

Casablanca

3450$

Pipes and Piping Systems Optimisation

16, Nov 2025 20, Nov 2025

Riyadh

3250$

Pipes and Piping Systems Optimisation

24, Nov 2025 28, Nov 2025

Istanbul

3450$

Pipes and Piping Systems Optimisation

30, Nov 2025 04, Dec 2025

Jeddah

3250$

Pipes and Piping Systems Optimisation

07, Dec 2025 11, Dec 2025

Manama

3250$

Pipes and Piping Systems Optimisation

14, Dec 2025 18, Dec 2025

Beirut

3250$

Pipes and Piping Systems Optimisation

22, Dec 2025 26, Dec 2025

Singapore

5450$

Pipes and Piping Systems Optimisation

28, Dec 2025 01, Jan 2026

Beirut

3250$

View course

View course

View course

View course

View course

View course