Hotel Meeting Room

Hotel Meeting Room

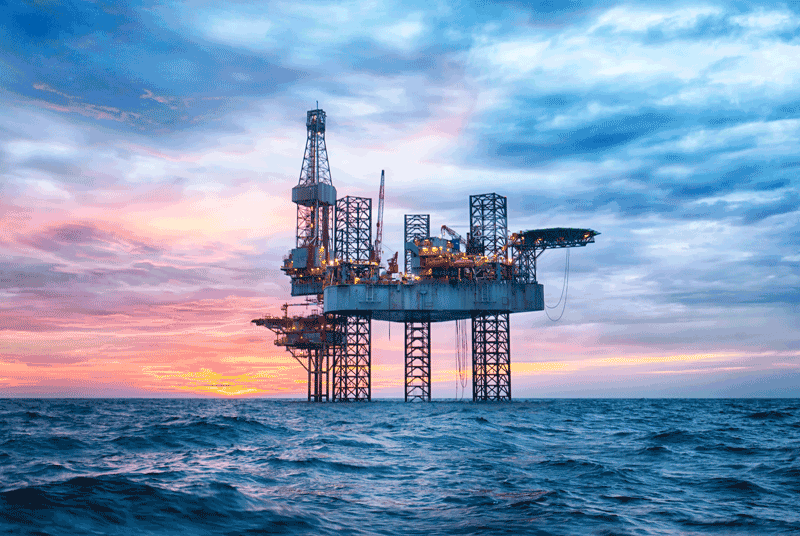

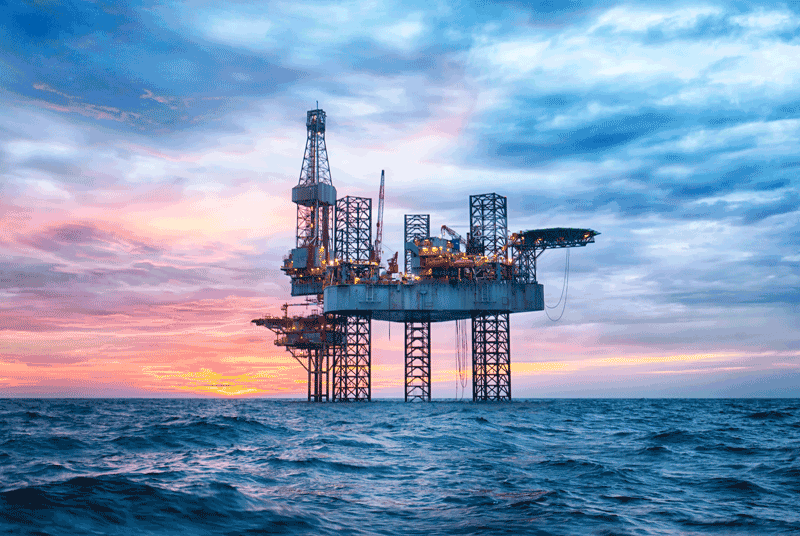

Petroleum, Oil , Gas Training Courses

Petroleum, Oil , Gas Training Courses

Hotel Meeting Room

Hotel Meeting Room Prague

Prague

Classroom

Overview ?

In an industrial situation where it is required to measure and control some aspect of a process, it is often the application of the knowledge and the ingenuity of the Engineer or Technician which is relied upon to solve the measurement and control problem. Therefore a fundamental understanding of the principle of operation of a range of sensors/transducers and instrumentation techniques applicable in an industrial situation combined with a working knowledge of Process control techniques and tuning methods equips the Engineer or Technician with the necessary skills and makes them invaluable in their workplace

The attendees will investigate the concepts of instrumentation and measurement and will acquire the knowledge relating to the characteristics and properties of the variables being measured. Moreover, the delegate will gain an understanding of the Process control systems and methods used in a modern industrial system

This is a practical and hands-on course and where applicable, theoretical studies will be supplemented with practical activities where the delegate will have the opportunity to design, develop, build, test and evaluate their own instrumentation systems

Introduction to Instrumentation systems and Process variables. Symbols and units used and sample calculations

Temperature Measurement techniques

Strain measurement

Investigation of Pressure and Flow measurement

Ultrasonic techniques for non-invasive process measurement

Practical activities to design, build, calibrate and signal condition a typical sensor application

To give an understanding of the principles and practice of a range of sensors and transducers

By using a hands-on approach, enable the delegate to investigate the operation of an instrumentation system through designing, building and testing typical sensor combined with appropriate signal conditioning circuits

To allow the delegate to become familiar and confident with a range of measurement techniques

To understand the concepts of Process Control and acquire the knowledge relating to the characteristics and properties of a process variable being measured

To disseminate and share experience and knowledge with other delegates through open session discussions hence broadening the knowledge base of all

To become familiar and knowledgeable with PID control and develop the ability to ‘tune’ a process control system using PID control

To have the confidence and knowledge to apply the above techniques and principles to solve an unfamiliar and bespoke measurement situation in the workplace

The seminar is delivered via a series of mixed activities which will at times involve delegate participation. Theoretical content is delivered by informal lecture and discussion and supplemented where appropriate with tutorial sessions using worked examples. An opportunity is given for delegates to perform their own calculations based on sample systems

An important part of the program is the hands-on aspect. Approximately a quarter of the total time will be devoted to practical activities. Delegates will acquire the skills to design their own instrumentation system from a given sensor(s) and specification and also, using relevant software, acquire the skills to ‘tune’ a process control system

By attending this seminar the delegate will return to their company more confident in the knowledge and use of sensors and instrumentation systems generally.

Be equipped with new skills and knowledge which must impact positively within the company structure

Be able to evaluate the suitability and application of current in-house instrumentation and control systems and offer guidance and advise on whether such systems may be modified or improved

Consequently be able to leverage their skills to potentially cause an increase within the plant or process in term of overall productivity and efficiency through analysis of current systems

Be better equipped to advise on new system installations in terms of sensor choice and specification, system monitoring techniques and circuit design

Potentially through their newly acquired knowledge be able to advise on in-house design of plant process and instrumentation systems thereby negating or at least reducing the dependency on external agencies and vendors

Therefore potentially contribute towards and result in plant and process cost reductions leading to financial savings for the company

The delegate will benefit personally from attendance of this seminar and will enhance their own knowledge base and level of confidence in the area of measurement systems and Process Control Engineering.

Understand the major technologies used in the measurement of flow, temperature, pressure, strain and level

Review the construction and operation of the most important sensors and transducers and their application in process measurement systems

Evaluate and select the most appropriate sensor technology for a given instrumentation system

Design, build and test using a given specification and sensor, their own instrumentation system

Identity components and features of a Process control system

Calibrate and signal condition the above system and take measurements from the system

Understand the limitations of Open loop systems and be aware of the inherent problems associated with Closed loop negative feedback systems

Optimise control by tuning a system using relevant software

Course schedule and layout

Introduction to Sensors, Transducers and Instrumentation Systems

Examples

Terms and definitions associated with Instrumentation systems, including;

Maximum error

Hysteresis

Repeatability

Sensitivity

Resolution

Span

Response time

Examples

Process Variables

Mass flow

Volumetric flow rate

Pressure

Viscosity

Turbidity

Examples

Principle of Strain Measurement – tension, compression, stress, strain, Youngs modulus

Principle of operation, application and installation considerations

Gauge types – principle of operation and configurations

Examples

Principles of Pressure measurement

Devices; principle of operation, application and installation considerations of:

Diaphragms

Bellows

Capacitive devices

Fibre Optic pressure measurement techniques

Principles of flow measurement

Reynolds number

Devices; principle of operation, application and installation considerations of Invasive types:

Coriolis Flowmeter

Differential Pressure type flowmeters

Orifice plate

Venturi tube

Flow nozzle

Dall flow tube

Electromagnetic flowmeters

Devices; principle of operation, application and installation considerations of Non invasive types:

Practical activity 1 – Design and Calibrate liquid level process measurement system

Temperature scales

Devices; principle of operation, application and installation considerations of:

Resistance temperature detectors (RTD’s)

Thermistors

Thermocouples

Radiation Pyrometers

Examples

Principle of single point and continuous level measurement techniques

Direct and indirect level measurement techniques

Devices; principle of operation, application and installation considerations of:

Ultrasonic techniques

Capacitive techniques

Pressure techniques

Principles and applications of Ultrasonic techniques for non-invasive measurement

Doppler shift and transit techniques

Principle of operation, application and installation considerations of Non-invasive flow measurement

Ultrasonic flowmeters

Practical activity 2 – Design and Calibrate liquid level process measurement system

Control Strategies

Block diagram representation

Control components

Servomechanisms and Regulators

Open and closed loop systems

Negative Feedback (NFB)

Transfer Functions

1st and 2nd order systems

Examples – Transfer functions and Closed Loop systems

ON/OFF control

Two step control action

Proportional control

Proportional band vs. proportional gain

Proportional offset

Reset

Integral action

Integral windup

Derivative action

PID control

Practical activity 3 – Design and Calibrate (thermocouple) temperature measurement system

Stability

System response

Bode plot

Nyquist plot

Load disturbances and offset

Empirical methods of setting Controllers

Open loop reaction curve method (Ziegler-Nichols)

Default and typical settings

Closed loop continuous cycling method (Ziegler-Nichols)

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Oil & Gas Operational Safety Industrial Instrumentation and Modern Control Systems

15, Dec 2025 19, Dec 2025

Munich

5250$

Oil & Gas Operational Safety Industrial Instrumentation and Modern Control Systems

22, Dec 2025 26, Dec 2025

Prague

5250$

Oil & Gas Operational Safety Industrial Instrumentation and Modern Control Systems

29, Dec 2025 02, Jan 2026

Munich

5250$

View course

View course

View course

View course

View course

View course