Hotel Meeting Room

Hotel Meeting Room

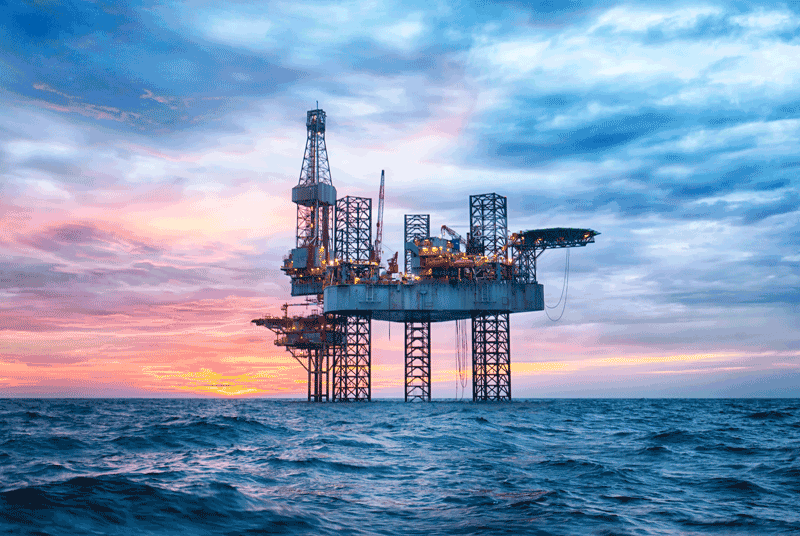

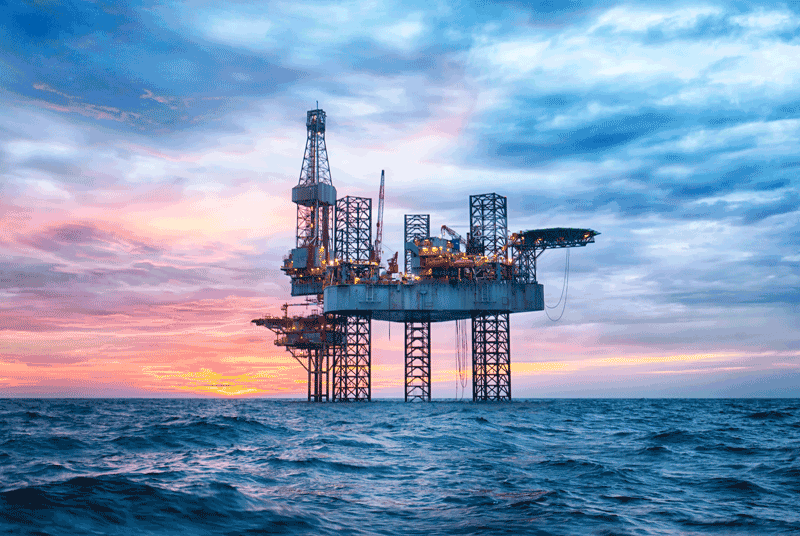

Petroleum, Oil , Gas Training Courses

Petroleum, Oil , Gas Training Courses

Hotel Meeting Room

Hotel Meeting Room Istanbul

Istanbul

Classroom

Overview ?

Appropriate material selection is the cornerstone of pressure equipment and piping design, operation and maintenance. Engineers must select materials of construction that provide adequate strength at operating temperatures and pressures, in compliance with applicable construction codes and with regard to their resistance to corrosion and other likely degradation mechanisms, as well as to cost-effectiveness. The acceptability of materials is controlled by the relevant Codes. The ultimate selection of the correct material is the responsibility of the design or fabrication engineer. By listing the design’s allowable stresses, the Codes do limit the materials that can be chosen. Only those materials that meet certain requirements as listed in the specifications should be used. The mechanical integrity, safety, and cost-effective operation of plants depend on the in-service performance of the materials of construction throughout the plant life cycle.

Metallurgy is a complex science but a general understanding of the major principles is essential to the plant engineers and inspectors This course provides comprehensive and practical understanding of engineering materials and guidance on the methods and best industry practices for the selection of the appropriate materials of construction for specific applications while simultaneously satisfying service requirements, construction Code requirements, and least life cycle costs over the entire plant life.

This course will provide a practical overview of ASME BPVC Section II – Materials, as well as some relevant information from the BPVC Section VIII Div.1 and B31.3 Process Piping

This course provides comprehensive and practical understanding of engineering materials and guidance on the methods and best industry practices for the selection of the appropriate materials of construction for specific applications while simultaneously satisfying service requirements, construction Code requirements, and least life cycle costs over the entire plant life. This course will provide a practical overview of ASME BPVC Section II – Materials, as well as some relevant information from the BPVC Section VIII Div.1 and B31.3 Process Piping

This course builds on a focused and practical coverage of engineering materials properties and selection and provides a structured approach to predict, monitor and assess the materials performance in service with the objective of ensuring plant integrity, safety and cost-effective operation

Assist participants to clearly understand that the appropriate selection of materials of construction for pressure equipment is the cornerstone of safe, reliable and costeffective plant operation.

Enhance participants’ awareness of key requirements of relevant design and operation standards and industry practices such as ASME B&PVC and B31.3; ASTM Material Specifications, API 571, 580, 581, 578 and 579, and others.

Provide guidelines to participants to identify and locate in-service degradation and appropriate tools for condition assessment and making sound run/repair/replace decisions. Make participants recognize that although all flaws detected by inspection must be evaluated, not all flaws need to be repaired. The proper application of API Std 579-1/ASME FFS-1 for fitness-for-service assessment may obviate the need for some repairs and result in reduced maintenance cost and downtime

This course is particularly valuable for refinery, petrochemical and process plant mechanical and process engineers, technical professionals, inspectors, maintenance personnel, as well as for project and consulting engineers and engineering and technical personnel involved in plant mechanical integrity and reliability.

The company will achieve improved financial performance through the proper selection of materials of construction based on total life cycle cost principles.

The company will be able to achieve measurable improvement in mechanical integrity through improved materials performance and reduced likelihood of failures.

The company will be able to enhance its ability to use risk-based inspection and maintenance resulting in lower life cycle costs while complying with codes and standards, and other regulatory requirement.

Participants will be more able to actively contribute towards reducing the probability of serious failures in pressure equipment and piping systems.

Participants will enhance their competence and productivity thereby enhancing their competence and performance level and making additional value added contributions to their organizations.

Engineering materials properties and selection criteria for specific applications with view to achieving optimum life cycle costs while complying with codes and regulations.

Construction codes, standards and recommended practices covering design of pressure equipment and piping systems.

Identification and assessment of active degradation mechanisms and the failures they may cause.

Hazard identification and risk analysis and management.

Application of risk-based methodologies in inspection and maintenance.

Fitness-For-Services assessments.

The course combines sound engineering principles, methods, and applicable codes & standards and best industry practices. Actual major incidents as well as industry experience will be reviewed in depth to reinforce every topic.

Metals – Ferrous and non-ferrous

Carbon steel

o Alloying elements added to iron base – carbon, manganese, and silicon

o Effect of alloying elements on end properties and on fabrication processes

o Impurities and their effect – sulfur, phosphorus

Alloy steel

o Effects of alloying elements

o Stainless steels

Specialty alloys

o Corrosion resistant alloys

o High temperature alloys

o Erosion resistant alloys

Refractory materials – Types and applications – Examples: Titanium and zirconium

Clad Materials – Types; production methods; and typical applications

Composite materials – Classes, types and applications

Non-Metallic materials – Plastics, ceramics

Surface engineered coatings/overlays – Types, specifications and applications

o Organic coatings

o Metallic coatings

o Corrosion resistant cladding

o Corrosion resistant / hard-surface welding

o Thermal spray coatings

o Plasma transferred arc (PTA) welded overlays

The structure of metals and alloys

Imperfections in metals and alloys

Chemical composition – Unified numbering system (UNS)

Physical properties – melting temperature, the thermal conductivity, electrical conductivity, the coefficient of thermal expansion, and density

Mechanical properties – Base metals, filler metal and completed welds

Tensile and yield strength, ductility, hardness and toughness

Heat treatment and effect on material properties

Forming and forging

Casting

Welding processes – main technologies and consumables currently used in industry

Weldability – Carbon equivalent; Shaeffler and WRC diagrams

Preheat and Post-Weld heat treatment (PWHT) – Code (B&PV and B31) rules

Weld imperfections (discontinuities) commonly encountered with welding processes

This Section contains rules relating to the qualification of welding and brazing procedures as required by other code sections for component manufacture

Welding procedure specification (WPS)

Procedure qualification record (PQR)

Welder performance qualification (WPQ)

Life cycle cost considerations

Factors in material selection in petroleum refineries- type of refinery; type of crude oil processed; service conditions in specific process unit/application, expected service

Oxidation resistance – scale formation

Guidelines on the maximum temperature of use of carbon steel and alloy materials

Creep properties – The Larson-Miller parameter (LMP)

Fatigue properties – Fatigue design (S-N) curves

ASME Boiler and Pressure Vessel and Piping Construction Codes

o Allowable stresses

o Constraints and limitations

o P-Number identificat

ASTM – Some common material specifications for piping, plates, forgings and castings

API RP 941 – Steels for hydrogen service at elevated temperatures and pressures in petroleum refineries and petrochemical plants

NACE MR 0175/ISO 15156 ‘Petroleum and Natural Gas Industries – Materials for Use in H2S-containing Environments in Oil and Gas Production – Parts 1, 2 and 3′

Oxidation resistance – scale formation

NACE MR0103 ‘Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments’

PIP (Process Industry Practices) Standards – Example: PIP Piping Material Specification 1CS2S01 Class 150, Carbon Steel, Socket Weld, 0.125 C.A. Process.

Fatigue properties – Fatigue design (S-N) curves

Overview of ASME B&PVC Section II ‘Materials Specifications’ – This Section compiles material specifications and material properties for materials used in the construction of ASME components. It contains four parts:

o Part A-Ferrous Material Specifications

o Part B-Nonferrous Material

o Part C-Specifications for Welding Rods

o Part D-Properties-(Customary)

Refineries and petrochemical plants

Power plants

Pressure vessels

Piping valves and fittings

Pumps

Ageing is not about how old equipment is; it’s about knowledge of its condition, and how that is changing over time

Indicators or symptoms of ageing Failure Modes and Mechanisms in Materials

Degradation processes – (e.g. corrosion, erosion)

Excessive elastic deformation – (e.g. buckling)

Fracture – (e.g. fatigue, brittle fracture)

This document provides background information on damage that can occur to equipment in the refining and other process industries. It covers over 60 damagemechanisms. It is also an excellent reference for inspection, operations, and maintenance personnel.

Overview

Case study

Objectives and methodologies (e.g. X-Ray Fluorescence and Optical Emission Spectroscopy)

ASTM- E1916

Pipe Fabricator Institute

PFI-ES42

API 578

MSS SP-137-2007

Material Test Reports

Definition, scope, and key elements – hardware and software issues, human factor,

Potential threats to technical integrity in a hazardous environment

Regulatory requirements – SH&E, OSHA, SEVESO II

Life cycle implications – design/operation/maintenance, management of change Inspection Strategies and Methods

Real function of inspection

Planning and strategies Inspection Strategies and Methods (continued)

Overview of API RP 580 and RBD 581 – Risk-Based Inspection

Overview of API RP 577 Welding Inspection and Metallurgy Non-Destructive Examination (NDE) Methods and Their Application

Capability of the applicable inspection method vs. discontinuity

New developments in NDE methods

Overview of ASME B&PVC Section V ‘Nondestructive Examination’

This section contains requirements and methods for non-destructive examination

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

16, Feb 2025 20, Feb 2025

DUBAI

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

24, Feb 2025 28, Feb 2025

Kuala Lumpur

3750$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

02, Mar 2025 06, Mar 2025

Amman

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

09, Mar 2025 13, Mar 2025

Marrakesh

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

16, Mar 2025 20, Mar 2025

Sharm ElShaikh

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

23, Mar 2025 27, Mar 2025

Doha

4000$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

30, Mar 2025 03, Apr 2025

Casablanca

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

06, Apr 2025 10, Apr 2025

Riyadh

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

14, Apr 2025 18, Apr 2025

Istanbul

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

20, Apr 2025 24, Apr 2025

Jeddah

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

27, Apr 2025 01, May 2025

Manama

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

04, May 2025 08, May 2025

Beirut

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

04, May 2025 08, May 2025

Khobar

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

12, May 2025 16, May 2025

Singapore

5450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

18, May 2025 22, May 2025

Kuwait

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

25, May 2025 29, May 2025

DUBAI

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

02, Jun 2025 06, Jun 2025

Kuala Lumpur

3750$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

08, Jun 2025 12, Jun 2025

Amman

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

15, Jun 2025 19, Jun 2025

Marrakesh

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

22, Jun 2025 26, Jun 2025

Sharm ElShaikh

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

29, Jun 2025 03, Jul 2025

Doha

4000$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

06, Jul 2025 10, Jul 2025

Casablanca

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

13, Jul 2025 17, Jul 2025

Riyadh

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

21, Jul 2025 25, Jul 2025

Istanbul

3450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

27, Jul 2025 31, Jul 2025

Jeddah

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

03, Aug 2025 07, Aug 2025

Manama

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

10, Aug 2025 14, Aug 2025

Beirut

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

18, Aug 2025 22, Aug 2025

Singapore

5450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

24, Aug 2025 28, Aug 2025

Kuwait

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

01, Sep 2025 05, Sep 2025

Berlin

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

08, Sep 2025 12, Sep 2025

Brussels

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

15, Sep 2025 19, Sep 2025

Zurich

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

22, Sep 2025 26, Sep 2025

Trabzon

4000$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

29, Sep 2025 03, Oct 2025

Beijing

5450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

06, Oct 2025 10, Oct 2025

Amsterdam

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

13, Oct 2025 17, Oct 2025

Bangkok

5450$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

19, Oct 2025 23, Oct 2025

Muscat

3250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

27, Oct 2025 31, Oct 2025

Milan

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

27, Oct 2025 31, Oct 2025

Toronto

6000$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

03, Nov 2025 07, Nov 2025

Barcelona

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

10, Nov 2025 14, Nov 2025

London

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

16, Nov 2025 20, Nov 2025

Cairo

2950$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

24, Nov 2025 28, Nov 2025

Geneva

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

01, Dec 2025 05, Dec 2025

Vienna

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

08, Dec 2025 12, Dec 2025

Munich

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

15, Dec 2025 19, Dec 2025

Prague

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

22, Dec 2025 26, Dec 2025

Rome

5250$

Materials of Construction for Process Equipment & Piping Systems “ Selection and In_Service Performance

29, Dec 2025 02, Jan 2026

Prague

5250$

View course

View course

View course

View course

View course

View course