Hotel Meeting Room

Hotel Meeting Room

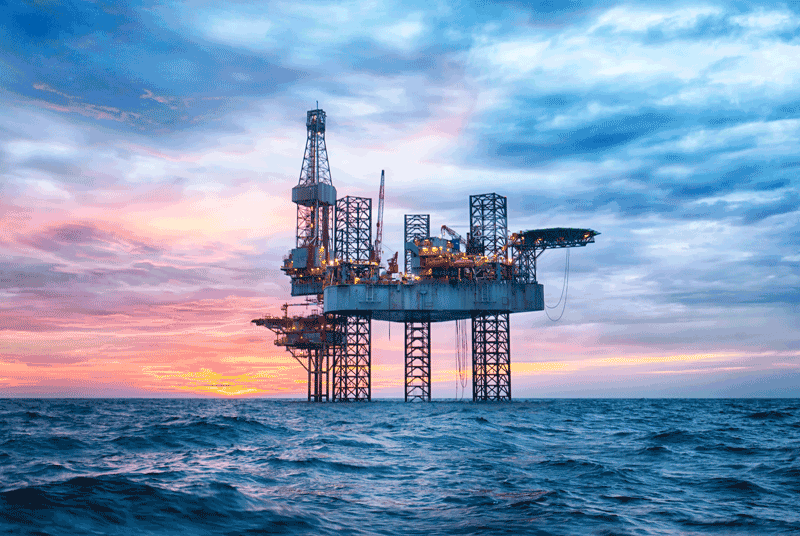

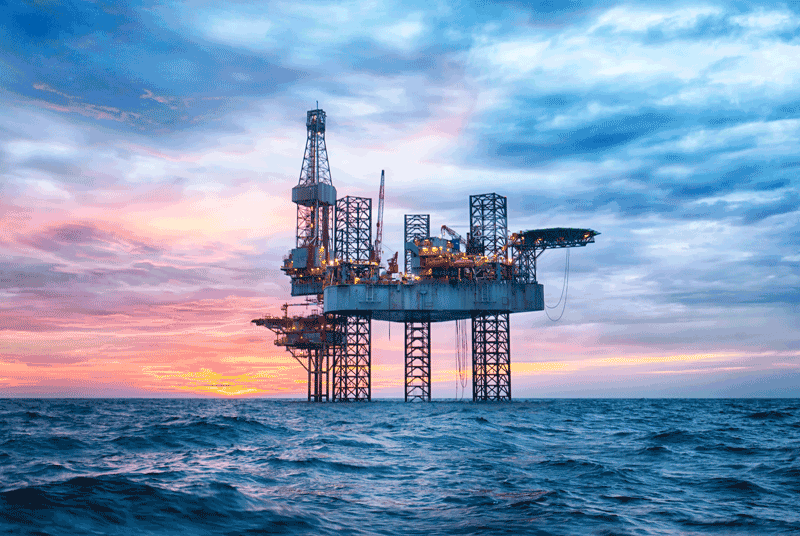

Petroleum, Oil , Gas Training Courses

Petroleum, Oil , Gas Training Courses

Hotel Meeting Room

Hotel Meeting Room Muscat

Muscat

Classroom

Overview ?

This programme provides a comprehensive understanding of the various types of reciprocating, rotary, and dynamic compressors and pumps. This includes trunk piston, sliding crosshead piston, diaphragm, rotary screw, straight lobe, sliding vane, liquid ring, centrifugal, and axial compressors as well as piston pumps, plunger pumps, rotary pumps, screw pumps, two- and three-lobe pumps, cam pumps, vane pumps, bellows-type metering pumps, diaphragm pumps, canned motor pumps, and centrifugal pumps. Bearings are also covered thoroughly. The characteristics, selection criteria, sizing calculations, sealing arrangements, common problems, repair techniques, as well as the preventive and predictive maintenance of these compressors and pumps are covered in detail.

This programme is a MUST for those who use this equipment. It covers how compressors, pumps, and bearings operate and provides the guidelines and rules that must be followed for their successful application.

The instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all the delegates gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective. The participants will learn by case studies. They will be able to apply all the concepts to their own organization.

This programme provides indepth understanding of the operation, selection, sizing, applications, sealing arrangements, troubleshooting, and maintenance of all types of compressors, pumps, and bearings. All the methods used to enhance the performance, reliability, troubleshooting, and maintenance of this equipment are discussed in detail. This programme includes also detailed coverage of mechanical seals, compressor and pump drivers, compressor surge, choking, surge prevention systems, and anti-choking systems. Dry seals and magnetic bearings are also covered in detail in this programme.

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Compressor & Pump Technology

20, Oct 2025 31, Oct 2025

Beijing

7450$

Compressor & Pump Technology

27, Oct 2025 07, Nov 2025

Amsterdam

7450$

Compressor & Pump Technology

03, Nov 2025 14, Nov 2025

Bangkok

7450$

Compressor & Pump Technology

09, Nov 2025 20, Nov 2025

Muscat

5250$

Compressor & Pump Technology

17, Nov 2025 28, Nov 2025

Toronto

7750$

Compressor & Pump Technology

24, Nov 2025 05, Dec 2025

Barcelona

7450$

Compressor & Pump Technology

01, Dec 2025 12, Dec 2025

London

7450$

Compressor & Pump Technology

07, Dec 2025 18, Dec 2025

Cairo

4450$

Compressor & Pump Technology

15, Dec 2025 26, Dec 2025

Geneva

7450$

Compressor & Pump Technology

22, Dec 2025 02, Jan 2026

Vienna

7450$

Compressor & Pump Technology

29, Dec 2025 09, Jan 2026

Geneva

7450$

View course

View course

View course

View course

View course

View course