Hotel Meeting Room

Hotel Meeting Room

Maintenance Planning, Process Engineering , Instrumentation Training Courses

Maintenance Planning, Process Engineering , Instrumentation Training Courses

Hotel Meeting Room

Hotel Meeting Room Marrakesh

Marrakesh

Classroom

Overview ?

Plant integrity and reliability is the cornerstone of process plant optimization. For optimization benefits to be sustainable, production interruptions must be kept to a minimum which requires effective management of degradation processes that affect equipment and systems and effective inspection and maintenance strategies, plans and methods. Plant optimization can be an effective way to achieve improved profitability without the large investment associated with building a new plant.

Common industrial processes and systems, such as steam, cooling water, process heating, and electric motors consume most of the energy and offer significant opportunities for savings. Process changes such as advanced controls, new catalysts, and new technologies also present opportunities for plant optimization. This course will provide a comprehensive review of the various aspects of process plant integrity as the essential foundation for sustainable plant profitability and optimization.

The course combines presentations and discussions of topics covered with relevant practical examples. It combines sound engineering and economic principles, methods, and best industry practices and enforces the learnings with Case Studies and Question & Answer workshops to maximize the benefits to the participants.

Planning and predictive maintenance of plant is vital to the budgetary success of the operations organisation. On completion of this seminar the delegate will be able to critically analyse the methodologies employed within the organisation and instigate improvements where required.

Technical knowledge is key to effective control and peer respect within any maintenance organisation; when this is achieved personal satisfaction follows. This seminar will give the delegate the required level of technical knowledge and skill to achieve that personal satisfaction.

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

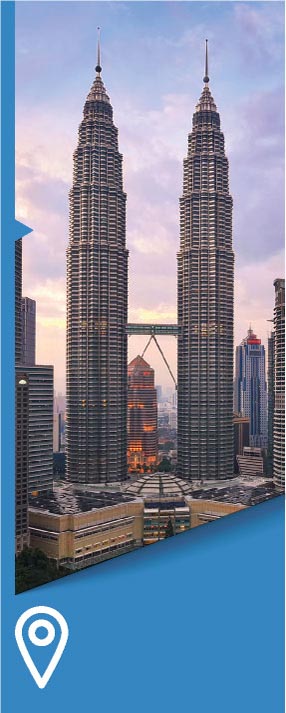

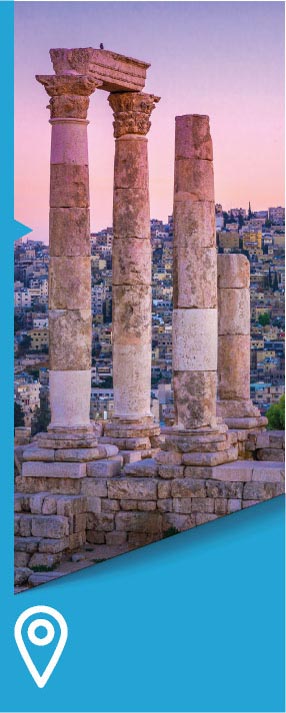

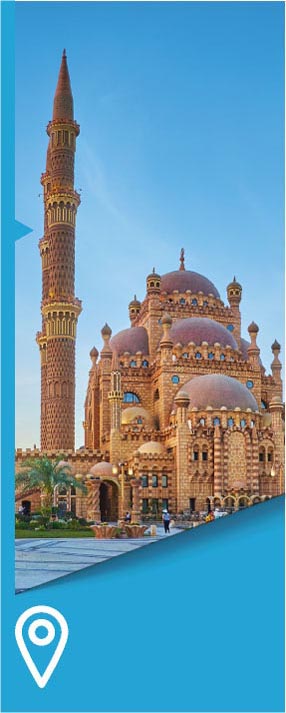

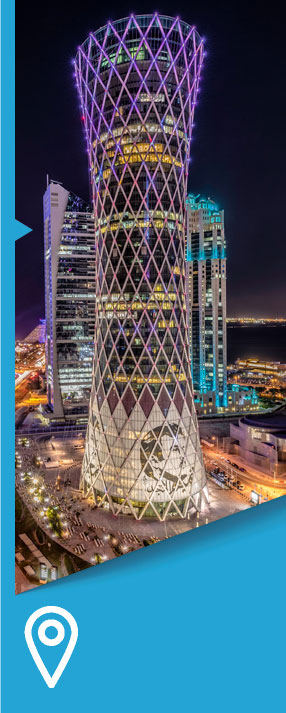

City

Price

View course

View course

View course

View course

View course

View course