Hotel Meeting Room

Hotel Meeting Room

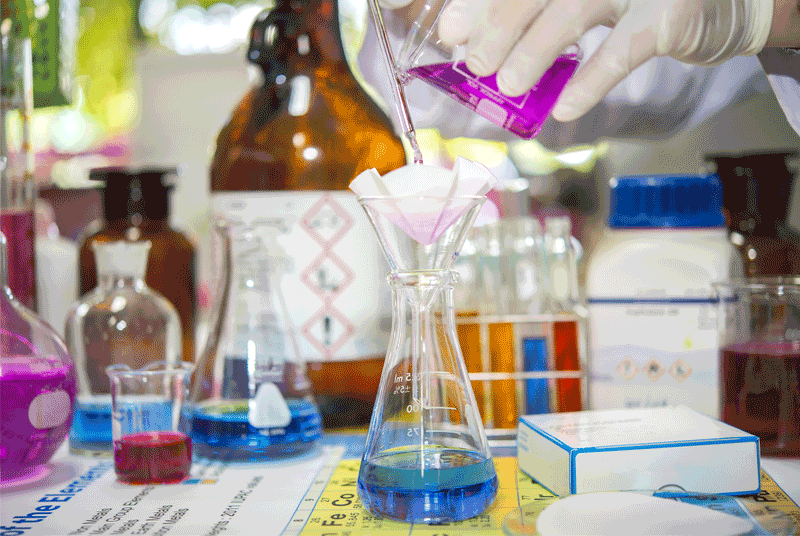

Chemical, Mechanical Engineering Training Courses

Chemical, Mechanical Engineering Training Courses

Hotel Meeting Room

Hotel Meeting Room Amman

Amman

Classroom

Overview ?

Welding is a common and a very important joining process in most industries, and of particular importance in the chemical, oil and gas industries, including for example, pipelines and storage tanks.

This 5-day training programme aim to provide the fundamental principles of welding and welding techniques, helping participants recognise various welding processes.

The course combines presentations and discussions of topics covered with relevant examples. It combines knowledge of fundamental principles related to welding processes, methods, and applicable standards and best industry practices and enforces learning with Question & Answer sessions to maximise the benefits to the participants.

Videos and computer simulation will be presented to emphasise relevant applications Relevant case studies will also be included.

Participants will be provided with comprehensive course notes and copies of presentation material that will be very valuable for detailed study and future reference.

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Welding Technology

19, Oct 2025 23, Oct 2025

Kuwait

3250$

Welding Technology

26, Oct 2025 30, Oct 2025

DUBAI

3450$

Welding Technology

03, Nov 2025 07, Nov 2025

Kuala Lumpur

3750$

Welding Technology

09, Nov 2025 13, Nov 2025

Amman

3250$

Welding Technology

16, Nov 2025 20, Nov 2025

Marrakesh

3450$

Welding Technology

23, Nov 2025 27, Nov 2025

Sharm ElShaikh

3250$

Welding Technology

30, Nov 2025 04, Dec 2025

Doha

4000$

Welding Technology

07, Dec 2025 11, Dec 2025

Casablanca

3450$

Welding Technology

14, Dec 2025 18, Dec 2025

Riyadh

3250$

Welding Technology

14, Dec 2025 18, Dec 2025

Khobar

3250$

Welding Technology

22, Dec 2025 26, Dec 2025

Istanbul

3450$

Welding Technology

28, Dec 2025 01, Jan 2026

Riyadh

3250$

View course

View course

View course

View course

View course

View course