Hotel Meeting Room

Hotel Meeting Room

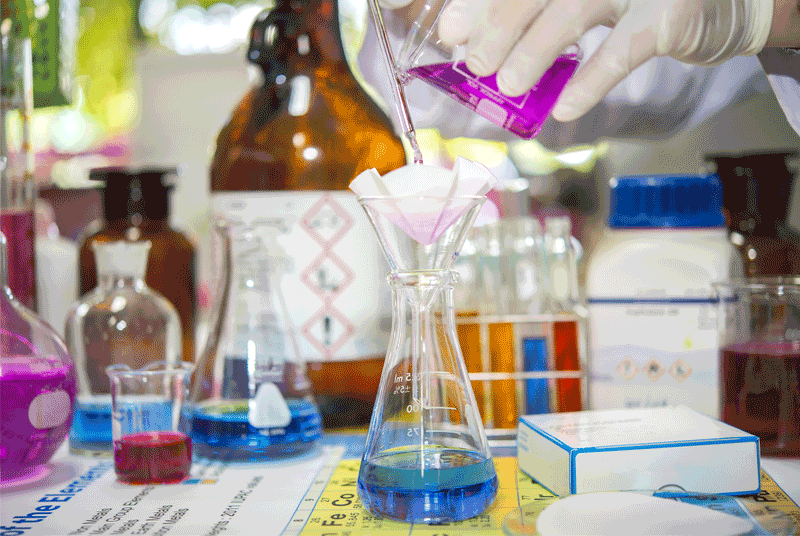

Chemical, Mechanical Engineering Training Courses

Chemical, Mechanical Engineering Training Courses

Hotel Meeting Room

Hotel Meeting Room Trabzon

Trabzon

Classroom

Overview ?

Progress in the development of high performance thermal systems has stimulated interest in methods to improve heat transfer, popularly called “heat transfer augmentation”. It has become second generation heat transfer technology. New techniques are primarily employed in a variety of thermal apparatuses encountered in process and chemical industries, including oil refineries and gas production plants as well as in power generation plants (thermal, nuclear, solar, geothermal, ocean thermal, etc.).

This course describes the most important and practical issues related to the optimum selection of various types of augmentation techniques employed for heat exchangers working with single-phase fluids (heaters or coolers) or with phase change fluids (evaporators, reboilers, condensers, etc.) The course will briefly survey basics of fluid flow and heat transfer in thermal apparatuses and continue with a detailed explanation of the most efficient passive (extended surfaces, fins, swirl flow devices, etc.) and active techniques (surface and fluid vibration etc.) for single phase flow as well as for fluids with phase-change (two-phase flows). Performance evaluation criteria (PEC) related to these techniques, as well as technical and economical issues, such as manufacturing costs, problems in operation, maintenance issues and others will be covered.

This course will be conducted with discussions and strong focus on teamwork within workshops and during lectures. Comprehensive workshops are included using real life cases as examples, where participants will learn calculation procedures and their results. Open fora will be held to emphasize key learnings and to inspire delegates to exchange view points based on professional experiences.

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Heat Transfer: Augmentation Techniques in the Process Industry

16, Feb 2025 20, Feb 2025

Beirut

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

24, Feb 2025 28, Feb 2025

Singapore

5450$

Heat Transfer: Augmentation Techniques in the Process Industry

02, Mar 2025 06, Mar 2025

Kuwait

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

10, Mar 2025 14, Mar 2025

Berlin

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

17, Mar 2025 21, Mar 2025

Brussels

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

24, Mar 2025 28, Mar 2025

Zurich

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

31, Mar 2025 04, Apr 2025

Trabzon

4000$

Heat Transfer: Augmentation Techniques in the Process Industry

07, Apr 2025 11, Apr 2025

Beijing

5450$

Heat Transfer: Augmentation Techniques in the Process Industry

14, Apr 2025 18, Apr 2025

Amsterdam

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

21, Apr 2025 25, Apr 2025

Bangkok

5450$

Heat Transfer: Augmentation Techniques in the Process Industry

27, Apr 2025 01, May 2025

Muscat

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

05, May 2025 09, May 2025

Toronto

6000$

Heat Transfer: Augmentation Techniques in the Process Industry

12, May 2025 16, May 2025

Barcelona

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

19, May 2025 23, May 2025

London

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

25, May 2025 29, May 2025

Cairo

2950$

Heat Transfer: Augmentation Techniques in the Process Industry

02, Jun 2025 06, Jun 2025

Geneva

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

09, Jun 2025 13, Jun 2025

Vienna

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

16, Jun 2025 20, Jun 2025

Munich

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

23, Jun 2025 27, Jun 2025

Prague

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

30, Jun 2025 04, Jul 2025

Rome

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

07, Jul 2025 11, Jul 2025

Jakarta

4000$

Heat Transfer: Augmentation Techniques in the Process Industry

13, Jul 2025 17, Jul 2025

Tunisia

3750$

Heat Transfer: Augmentation Techniques in the Process Industry

21, Jul 2025 25, Jul 2025

Marbella

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

28, Jul 2025 01, Aug 2025

Paris

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

04, Aug 2025 08, Aug 2025

Madrid

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

10, Aug 2025 14, Aug 2025

DUBAI

3450$

Heat Transfer: Augmentation Techniques in the Process Industry

18, Aug 2025 22, Aug 2025

Kuala Lumpur

3750$

Heat Transfer: Augmentation Techniques in the Process Industry

24, Aug 2025 28, Aug 2025

Amman

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

31, Aug 2025 04, Sep 2025

Marrakesh

3450$

Heat Transfer: Augmentation Techniques in the Process Industry

07, Sep 2025 11, Sep 2025

Sharm ElShaikh

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

14, Sep 2025 18, Sep 2025

Doha

4000$

Heat Transfer: Augmentation Techniques in the Process Industry

21, Sep 2025 25, Sep 2025

Casablanca

3450$

Heat Transfer: Augmentation Techniques in the Process Industry

21, Sep 2025 25, Sep 2025

Khobar

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

28, Sep 2025 02, Oct 2025

Riyadh

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

06, Oct 2025 10, Oct 2025

Istanbul

3450$

Heat Transfer: Augmentation Techniques in the Process Industry

12, Oct 2025 16, Oct 2025

Jeddah

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

19, Oct 2025 23, Oct 2025

Manama

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

26, Oct 2025 30, Oct 2025

Beirut

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

03, Nov 2025 07, Nov 2025

Singapore

5450$

Heat Transfer: Augmentation Techniques in the Process Industry

09, Nov 2025 13, Nov 2025

Kuwait

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

16, Nov 2025 20, Nov 2025

DUBAI

3450$

Heat Transfer: Augmentation Techniques in the Process Industry

24, Nov 2025 28, Nov 2025

Kuala Lumpur

3750$

Heat Transfer: Augmentation Techniques in the Process Industry

30, Nov 2025 04, Dec 2025

Amman

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

07, Dec 2025 11, Dec 2025

Marrakesh

3450$

Heat Transfer: Augmentation Techniques in the Process Industry

14, Dec 2025 18, Dec 2025

Sharm ElShaikh

3250$

Heat Transfer: Augmentation Techniques in the Process Industry

21, Dec 2025 25, Dec 2025

Doha

4000$

Heat Transfer: Augmentation Techniques in the Process Industry

22, Dec 2025 26, Dec 2025

Milan

5250$

Heat Transfer: Augmentation Techniques in the Process Industry

28, Dec 2025 01, Jan 2026

Sharm ElShaikh

3250$

View course

View course

View course

View course

View course

View course