Hotel Meeting Room

Hotel Meeting Room

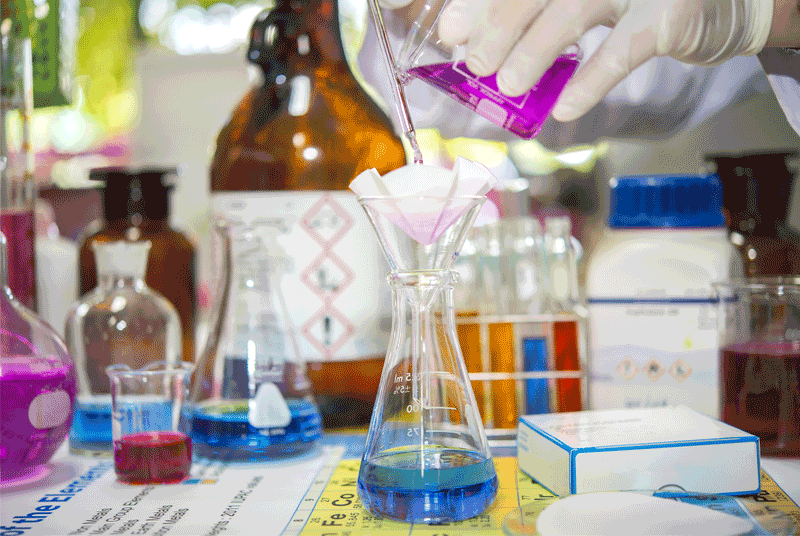

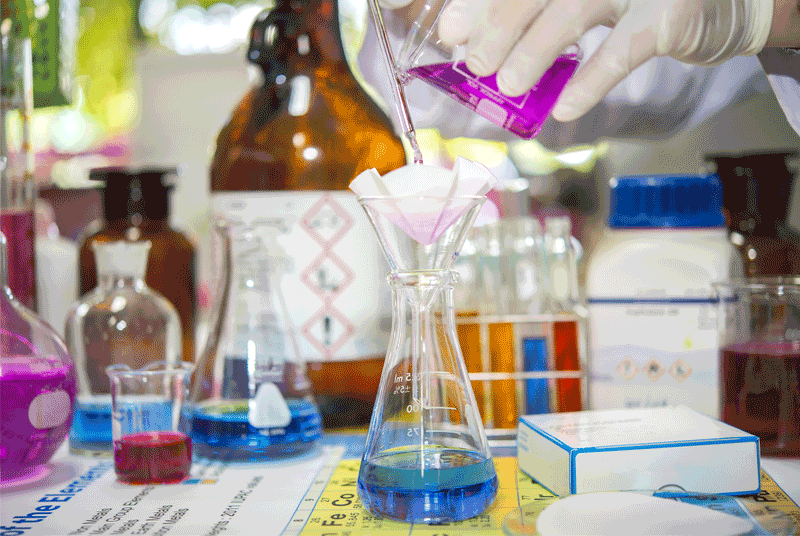

Chemical, Mechanical Engineering Training Courses

Chemical, Mechanical Engineering Training Courses

Hotel Meeting Room

Hotel Meeting Room Sharm ElShaikh

Sharm ElShaikh

Classroom

Overview ?

This course is a must if your company’s goals include reducing costs and preserving the lives of your employees because it delivers a wide range of pro-active, efficient troubleshooting skills. It has been proven that technical competence alone is no longer enough to ensure consistent operational performance. Excellent troubleshooting skills are considered a core competency for ‘Best-in-Class’ modern industrial companies. In the competitive world that we are living in, it is essential that we optimize our efforts to secure the desired outcomes, and this course will equip the delegate with the basic tools and understanding to make that happen.

The understanding of terminologies; tools and techniques

Apply a standard “Blue-Print” for problem analysis and resolution

How to utilize Maturity Indexing; Planning; and Protocols

Useful Case Studies; Exercises and Analysis

Learning the “Human Factors” as a Source of Error

Appreciate the difference and consequences between pro-active and reactive problem solving

Develop a structured approach to troubleshooting and problem solving

Understand continuous improvement in the way you run your processes

Implement teamwork and leadership principles; support and cooperation practices

Understand work practices which “allow” success in troubleshooting and problem solving

Employees who are responsible for leading and directing people to achieve and improve productivity levels

Those faced with the challenge of solving plant related problems

Production, Maintenance Engineering and Process Engineering personnel

Supervisors who are involved in the Operations / Maintenance function

Planners, Coordinators, Engineers and Technologists

This course will utilise a variety of proven adult learning techniques to ensure maximum understanding, comprehension and retention of the information presented. This includes a facilitative style with a combination of lecture, practical experience in the use of techniques, case studies and a high level of lively debate and sharing of ideas. Delegates will be encouraged to introduce problems of their own for discussion and analysis.

Defining the nature of problems

Utilising a Common Terminology

Techniques introduction

Tools introduction

Levels of Performance Standard

Critical Relationships

Application of Decision Logic

Practical Maturity Indexing

Relationships Analysis

Problem Analysis and Synthesis

Practical Use of Tools and Techniques

Project selection methods

Working practices – empowerment or impairment?

Group dynamics

Individual motivators: External vs. Internal Motivation

Developing Leadership Competence

Managing change via the Transition Matrix

Cross functional problem solving

Development of Maintenance strategy

Life Cycle Analysis, Design for Operation, Design for Maintenance

Variability Analysis

Strategies; Planning; and Protocols

Effect of improved “Fit” between critical parameters in Operations

Concepts, Tools and Techniques applied to problems

Configuration Management

Commercial Programs

The Critical stages of Data Maturity

Case Studies and Action Plans

Wrap up

Day 1

Asset Cost Management Introduction

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 2

Laying the Groundwork

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 3

Applying the Value based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 4

Ensuring the Continuity of the Value-based Process

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Day 5

Supporting Process that Lower Life-cycle costs

Definitions of reliability, maintenance & asset management

The total cost of maintenance

Best practice reliability and maintenance processes

Elements of asset management best practice

Auditing performance

Overview of TPM, RCM, BCM, QCM, and other asset management buzzword

Open discussion sessions

Training Methodology

Pathways Training and consulting adopts the newest techniques of human resources Training and consulting and, with the following:

Course name

Duration

City

Price

Process Plant Troubleshooting & Engineering Problem Solving

17, Feb 2025 21, Feb 2025

Bangkok

5450$

Process Plant Troubleshooting & Engineering Problem Solving

17, Feb 2025 21, Feb 2025

Vienna

5250$

Process Plant Troubleshooting & Engineering Problem Solving

24, Feb 2025 28, Feb 2025

Munich

5250$

Process Plant Troubleshooting & Engineering Problem Solving

03, Mar 2025 07, Mar 2025

Prague

5250$

Process Plant Troubleshooting & Engineering Problem Solving

10, Mar 2025 14, Mar 2025

Rome

5250$

Process Plant Troubleshooting & Engineering Problem Solving

17, Mar 2025 21, Mar 2025

Jakarta

4000$

Process Plant Troubleshooting & Engineering Problem Solving

23, Mar 2025 27, Mar 2025

Tunisia

3750$

Process Plant Troubleshooting & Engineering Problem Solving

30, Mar 2025 03, Apr 2025

Khobar

3250$

Process Plant Troubleshooting & Engineering Problem Solving

31, Mar 2025 04, Apr 2025

Marbella

5250$

Process Plant Troubleshooting & Engineering Problem Solving

07, Apr 2025 11, Apr 2025

Paris

5250$

Process Plant Troubleshooting & Engineering Problem Solving

14, Apr 2025 18, Apr 2025

Madrid

5250$

Process Plant Troubleshooting & Engineering Problem Solving

20, Apr 2025 24, Apr 2025

DUBAI

3450$

Process Plant Troubleshooting & Engineering Problem Solving

28, Apr 2025 02, May 2025

Kuala Lumpur

3750$

Process Plant Troubleshooting & Engineering Problem Solving

04, May 2025 08, May 2025

Amman

3250$

Process Plant Troubleshooting & Engineering Problem Solving

11, May 2025 15, May 2025

Marrakesh

3450$

Process Plant Troubleshooting & Engineering Problem Solving

18, May 2025 22, May 2025

Sharm ElShaikh

3250$

Process Plant Troubleshooting & Engineering Problem Solving

25, May 2025 29, May 2025

Doha

4000$

Process Plant Troubleshooting & Engineering Problem Solving

01, Jun 2025 05, Jun 2025

Casablanca

3450$

Process Plant Troubleshooting & Engineering Problem Solving

08, Jun 2025 12, Jun 2025

Riyadh

3250$

Process Plant Troubleshooting & Engineering Problem Solving

16, Jun 2025 20, Jun 2025

Istanbul

3450$

Process Plant Troubleshooting & Engineering Problem Solving

16, Jun 2025 20, Jun 2025

Milan

5250$

Process Plant Troubleshooting & Engineering Problem Solving

22, Jun 2025 26, Jun 2025

Jeddah

3250$

Process Plant Troubleshooting & Engineering Problem Solving

29, Jun 2025 03, Jul 2025

Manama

3250$

Process Plant Troubleshooting & Engineering Problem Solving

30, Jun 2025 04, Jul 2025

Milan

5250$

Process Plant Troubleshooting & Engineering Problem Solving

06, Jul 2025 10, Jul 2025

Beirut

3250$

Process Plant Troubleshooting & Engineering Problem Solving

14, Jul 2025 18, Jul 2025

Singapore

5450$

Process Plant Troubleshooting & Engineering Problem Solving

20, Jul 2025 24, Jul 2025

Kuwait

3250$

Process Plant Troubleshooting & Engineering Problem Solving

27, Jul 2025 31, Jul 2025

DUBAI

3450$

Process Plant Troubleshooting & Engineering Problem Solving

04, Aug 2025 08, Aug 2025

Kuala Lumpur

3750$

Process Plant Troubleshooting & Engineering Problem Solving

10, Aug 2025 14, Aug 2025

Amman

3250$

Process Plant Troubleshooting & Engineering Problem Solving

17, Aug 2025 21, Aug 2025

Marrakesh

3450$

Process Plant Troubleshooting & Engineering Problem Solving

24, Aug 2025 28, Aug 2025

Sharm ElShaikh

3250$

Process Plant Troubleshooting & Engineering Problem Solving

31, Aug 2025 04, Sep 2025

Doha

4000$

Process Plant Troubleshooting & Engineering Problem Solving

07, Sep 2025 11, Sep 2025

Casablanca

3450$

Process Plant Troubleshooting & Engineering Problem Solving

14, Sep 2025 18, Sep 2025

Riyadh

3250$

Process Plant Troubleshooting & Engineering Problem Solving

22, Sep 2025 26, Sep 2025

Istanbul

3450$

Process Plant Troubleshooting & Engineering Problem Solving

28, Sep 2025 02, Oct 2025

Jeddah

3250$

Process Plant Troubleshooting & Engineering Problem Solving

05, Oct 2025 09, Oct 2025

Manama

3250$

Process Plant Troubleshooting & Engineering Problem Solving

12, Oct 2025 16, Oct 2025

Beirut

3250$

Process Plant Troubleshooting & Engineering Problem Solving

20, Oct 2025 24, Oct 2025

Singapore

5450$

Process Plant Troubleshooting & Engineering Problem Solving

26, Oct 2025 30, Oct 2025

Kuwait

3250$

Process Plant Troubleshooting & Engineering Problem Solving

03, Nov 2025 07, Nov 2025

Berlin

5250$

Process Plant Troubleshooting & Engineering Problem Solving

10, Nov 2025 14, Nov 2025

Brussels

5250$

Process Plant Troubleshooting & Engineering Problem Solving

17, Nov 2025 21, Nov 2025

Zurich

5250$

Process Plant Troubleshooting & Engineering Problem Solving

24, Nov 2025 28, Nov 2025

Trabzon

4000$

Process Plant Troubleshooting & Engineering Problem Solving

01, Dec 2025 05, Dec 2025

Beijing

5450$

Process Plant Troubleshooting & Engineering Problem Solving

08, Dec 2025 12, Dec 2025

Amsterdam

5250$

Process Plant Troubleshooting & Engineering Problem Solving

15, Dec 2025 19, Dec 2025

Bangkok

5450$

Process Plant Troubleshooting & Engineering Problem Solving

21, Dec 2025 25, Dec 2025

Muscat

3250$

Process Plant Troubleshooting & Engineering Problem Solving

29, Dec 2025 02, Jan 2026

Bangkok

5450$

View course

View course

View course

View course

View course

View course